Abstracts:

Formulating live bacteria in emulsions

Wilson Poon

I will review current and future reasons for including live bacteria in products, and then focus on why and how one may want to include bacteria in emulsion droplets. Recent results from our group on encapsulating a model organism, motile Escherichia coli, in water-in-oil emulsion droplets will be discussed as a 'worked example' of some of the issues that may be encountered in preparing such formulations.

The secret life of Pickering emulsions

Paul Clegg

Edinburgh University

In many encapsulation applications it is attractive to use solid particles to stabilize emulsion droplets. The solid particles can be very strongly trapped at the liquid interfaces, leading to extremely stable emulsions. New approaches to encapsulation arise due to the rigidity of the interfaces and the possibility of preparing multiple emulsions in a single step. Here we will explore the sensitivity of these systems to the preparation approach, showing versatility and vulnerability in different regimes. Surprisingly, we will demonstrate that these Pickering emulsions can be highly dynamic: exchanging particles between droplets even while the emulsion remains stable.

Additives to prevent the malicious use of consumer chemicals

Andrew Laing

Partners: Home Office, QinetiQ, Ashland, University of Leeds

Many explosives encountered by law enforcement are manufactured from chemicals found in everyday household products or chemicals used by industry. In May 2014, the Home Office launched a research call to identify additives that can be used to modify household products or industrial chemicals to prevent the illicit manufacture of explosives or to cause harm while retaining the properties necessary for their legitimate use.

QinetiQ completed a Phase 1 feasibility study, in collaboration with the University of Leeds, which identified a number of additives that could, in principle, meet this aim. Explosives were prevented from being manufactured by two mechanisms: gelling and decomposition.

The research has now moved into Phase 2 where QinetiQ will be working with Ashland and the University of Leeds to develop formulations that meet the original aims of the call and are acceptable for consumers to use and industry to manufacture.

Characterization of theophylline and budesonide encapsulated PLA nanoparticles

Mira D Buhecha, Alison Lansley, Ananth Pannala

School of Pharmacy and Biomolecular sciences, University of Brighton, BN2 4GJ

Theophylline and budesonide co-encapsulated poly (lactic acid) (PLA) nanoparticles were synthesised using a modified double emulsion solvent diffusion (DESD) method. The aim of the work was to investigate their effects on the human bronchial epithelial (16HBE14o-) cell line by studying the toxicity of the NPs and the drug permeability. Further characterization was carried out by studying the in vitro pulmonary deposition using a multistage liquid impinger (MSLI) using a nebulized suspension of the nanoparticles and dry powder formulations using lactose carriers. At the highest concentration of nanoparticles suspension, the cell viability was reduced to approximately 70% of the controls for co-encapsulated nanoparticles (p<0.05). Reduced cell viability was only observed at a nanoparticle concentration of 5 mg/ml. The transport of the paracellular marker, FITC-dextran (FD4), across the 16HBE14o- cells was not altered when cells were treated with nanoparticle suspensions and drug solutions prepared at equivalent concentration, compared to the control (p>0.05). Initial studies indicated that the transport rate of theophylline and budesonide across 16HBE14o-cells was less when delivered using co-encapsulated nanoparticles than from their respective drug solutions at equivalent concentrations over a period of 24 hours. A total of 20% of theophylline and 5% budesonide was released, respectively from the nanoparticles. Approximately 100% of theophylline was delivered from equivalent theophylline solution and 20% of budesonide from equivalent concentration suspension. Dry powders synthesized using lactose showed large nanoparticle deposition in the upper airway (20%) which is ideal for treatment of local diseases. Nebulized nanoparticle suspensions showed deposition in upper and lower airways. Comparisons were made between co- and mono-encapsulated theophylline and budesonide nanoparticles.

Encapsulation by membrane emulsification

Richard G. Holdich, Marijana M. Dragosavac

Department of Chemical Engineering, Loughborough University, Loughborough, UK

Production of larger droplets of controlled diameter is becoming increasingly popular. Those droplets after additional treatment can be turned into particles and applied in industries as food and flavour encapsulates, controlled release depots under the skin, medical diagnostic particles, high value fillers, electronic ink capsules, ion exchange resins. Conventional devices for preparing emulsions apply more energy than needed for the production of droplets, leading to droplets with a wide size distribution and such devices are not suitable if temperature/sheer sensitive compounds should be encapsulated.

Membrane emulsification (ME) is a dispersion process to produce monosized droplets of one liquid phase (e.g. oil) in a second immiscible liquid phase (e.g. water) using low energy per unit volume where the shear stress applied on the membrane surface influences the droplet size. A new ME techniques (dispersion cell, torsional, oscillating and vibrating ME) developed at Micropore Technologies Ltd. UK in collaboration with Loughborough University were introduced for generating the shear on the membrane surface providing the possibility to generate larger droplets without risk of breakage with possibility for scaling up. Using these techniques it is possible to generate highly uniform drops/particle between 15 and 1000 µm.

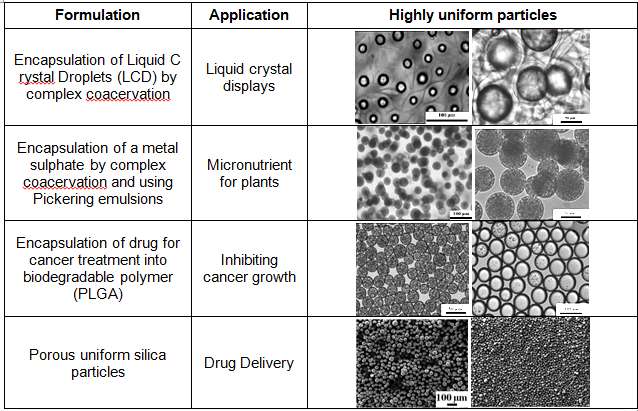

Table 1 Some of the particles successfully produced up to date using ME methods.

Paula F. De Castro and Dmitry G. Shchukin

Stephenson Institute for Renewable Energy, Chemistry Department, University of Liverpool, L69 7ZF, United Kingdom

Thermal energy storage has recently become a major interest since it can reduce the total energy consumption but also conserve the fossil fuels. Sensible heat storage systems have been using because of its simplicity but they present drawbacks such as a) intermittent sources, b) poor energy-storage density due to the large volume of the system required to store a small amount of energy and c) releasing of the storage heat at any temperature. In latent heat storage systems by using phase-change materials (PCMs), the energy-storage density of the system is considerably increased due to the latent heat involved, since they can absorb or release the equivalent thermal energy to their latent heat when undergoing the phase transition in a quasi-isothermal process(1) which makes those systems more reliable compared to the sensible ones. Among the disadvantages of PCMs are the low heat transfer, poor stability during energy uptake/release, and their difficulty to be handled in practical applications. In order to overcome these disadvantages encapsulation technology has extensively been used in PCMs in the last years(2).

Herein, we present an encapsulation methodology for the preparation of the new energy-enriched microcapsules based on polyurethane shell and loaded n-docosane as phase change materials for the heat storage. Morphological and thermal properties are also presented(3).

References

1. S.D. Sharma, H. Kitano and K.Sagara. Res. Rep. Fac. Eng. Mie. Univ. 2004, 29, 31-64.

2. A. Jamekhorshid, S.M. Sadrameli, M. Farid. Ren. Sust. Energy. Rev. 2014, 31, 531-542.

3. P.F. De Castro and D.G. Shchukin. Chem. Eur. J. 2015, 21, 11174-11179.

One-Pot Route to Liquid Encapsulation

Paul Findlay, Magda Warunek and Joseph Wilson

Revolymer Ltd

This paper will present a facile route to the preparation of core-shell encapsulates via the use of functional polymeric emulsifiers. These bespoke emulsifiers have the advantage of being able to emulsify and further cross-link a variety of dispersed phases, in particular hydrophobic oils and payloads, at low incorporation levels. This thereby eliminates the requirement of using reactive, and in some cases toxic, small molecule cross-linking agents such as formaldehyde or isocyanates. The surface functionality and charge on the formed capsules can be pre-controlled through the polymer composition. Additionally, the polymeric emulsifiers are prepared using an industrially-viable one-pot process. The authors will present recent findings at Revolymer where a series of model oils were encapsulated and their stabilities and release profiles determined.

Novel polymer microcapsules formed by host-guest complexation and their potential for encapsulation

Andrew Howe, Roger Coulston, Jing Zhang

Aqdot Ltd

Host-guest complexation can be used to link simple functionalised polymers in a shell with controllable permeability. Initial experiments used a microfluidic device to generate monodisperse water-based capsules into which molecular cargoes were incorporated with 100% efficiency (Zhang et al., Science, 2012 335 690). The polymers are linked together non-covalently by inclusion of hydrophobic/cationic monomers into a cucurbit[8]uril host in 2:1 ratio.

This presentation will describe the formation, properties and some applications of the microcapsules. The microcapsule can be formed by a wide range of procedures, the details of which are used to control the size and size distribution. The capsules maintain integrity after drying and re-swelling. The permeability of the microcapsules can be controlled via the composition and may be quantified by measuring retention of fluorescently labelled cargoes of different MW. Capsules can be designed to trigger release by selected mechanisms. Progress towards specific applications will be described and areas for potential future application touched upon.

In Aqdot, the novel and highly specific nature of cucurbit[n]uril host-guest complexes are under investigation for a wide range of application areas.

Yeast Biocapsules: More than just a carrier for food flavours

Craig Duckham

CD R&D Consultancy Services Ltd

Yeast cells can be used as biodegradable vehicles for the microencapsulation of a range of small molecule active ingredients including volatile food flavours. Despite there being a wide range of applications for this process using common baker’s or brewer’s yeast (Saccharomyces cerevisiae), for example in the food industry, the mechanism for uptake is still poorly understood. This has hampered the adoption of this technology into wider application areas including the development of sustained delivery crop protection formulations or the encapsulation of fat soluble vitamins and other functional ingredients. Studies carried out in collaboration with the University of Manchester using specifically synthesised molecular probes led to a clearer understanding of the encapsulation process and how the technology could be developed further to produce novel products.

Creation of Handmade Single Malt Whisky Liqueurs

Sophie Latinis

http://www.pittenweemchocolate.co.uk/

The perfect, artisan gift for the malt whisky connoisseur! An exclusive collaboration between The Pittenweem Chocolate Company and Belgian chocolate-makers.