Posters - abstract submission now OPEN. Please submit your poster to

Please submit your abstracts

We would now like to offer an opportunity to submit an abstract for this conference in the general field of functional films and coatings. Areas to be considered include novel routes to their manufacture, the properties that such products exhibit, whether in the area of thin films or coatings based on multicomponent formulations. Other topics could include the analysis of such material. The application areas can be anything from pharmaceutical, cosmetics, agrochemicals, veterinary, to smart materials such as inks and adhesives.

Authors of successful abstracts will be offered the opportunity to present a poster on the topic. Accompanying your standard A1/A0 poster PDF, you will also present your work as a recorded 3 minute presentation during the poster session where you will need to be available to answer both typed chat and oral questions. So please prepare your A1/A0 pdf poster and 3 minute recorded video presentation, and sent to

Abstracts should consist of a one- paragraph summary (ca 150 – 200 words) and the contact details of the authors (presenting author first) and affiliations.

This should be sent to

Accepted Poster Abstracts

Plasma Surface Treatment for Enhancing Liquid Retention in Plastic Meat Packaging

WCPC, Faculty of Science and Engineering, Swansea University, SA1 8EN, Swansea, UK

Management of meat exudate is still problematic to the fresh food packaging. The exudate gives an unappealing appearance in the packaged meat products and facilitates spoilage and growth of pathogenic microorganisms, accelerating the degradation of meat quality and safety. Different packaging solutions have been developed to scavenge the meat exudate in plastic packaging, such as soaking pads in plastic trays and foam trays with open-cell structure. However, the soaked pads and foam are non-recyclable and increase recycling complexity of plastic trays. Therefore, an innovative and fully recyclable plastic package is developed to act not only as primary packaging but also to scavenge the meat exudate. This is based on enhancing the performance of plastic packaging material itself through plasma treatment. Capillary recesses integrated into the plastic tray undergo localised plasma treatment to increase the wettability of the recesses and enhance their liquid pinning effect. This offers higher stability for liquid menisci and increases the retention capacity of the recesses. For PET substrates, an increase in liquid retention capacity of ~2.24 times is demonstrated for the recesses [1]. The new meat trays provide comparative capacity of liquid retention to the conventional absorbent pads while ensuring fully recyclable trays.

Spectrally Selective Coatings for Overhead Powerlines to Increase Ampacity and Reduce Power Losses

AssetCool

Email:

Spectrally Selective Coatings for Overhead Powerlines to Increase Ampacity and Reduce Power Losses Rachel Parker*, Oliver Higbee, Niall Coogan AssetCool;

INNOVATIVE SOLUTION TO OPTIMIZE THE FORMULATION & CURING OF FUNCTIONAL FILMS AND COATINGS

Yassine Nagazi, Giovanni Brambilla, Gérard Meunier

Formulaction, 3-5 Rue Paule Raymondis - 31200 Toulouse- France

Corresponding author:

The characterization of the microscopic dynamics of functional films & coatings is a very important step in every new development or quality control.

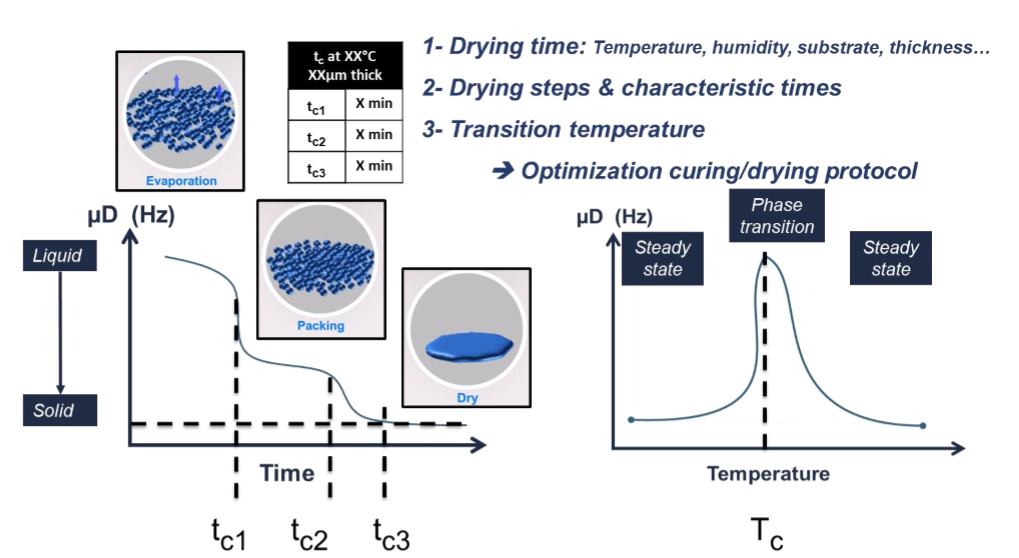

We use a dynamic light scattering technique to investigate the microstructure evolution (evaporation, packing, coalescence…) of a large panoply of materials at constant or increasing temperature (RT-250°C) and with humidity control. This technology allows to compare different formulation and to detect the characteristic steps (Drying/curing time, phase transition…) with a very handy sampling protocol on any substrate and a very high sensitivity.

We will present a new in-situ, non-invasive and handy method to better understand your different materials, allowing to:

Figure 1: (left) Typical drying kinetics & identification of the characteristic steps/times, (right) Microscopic dynamics of polymer film vs temperature

8 Tech Innovative, Palm Desert, USA, 92260

Email:

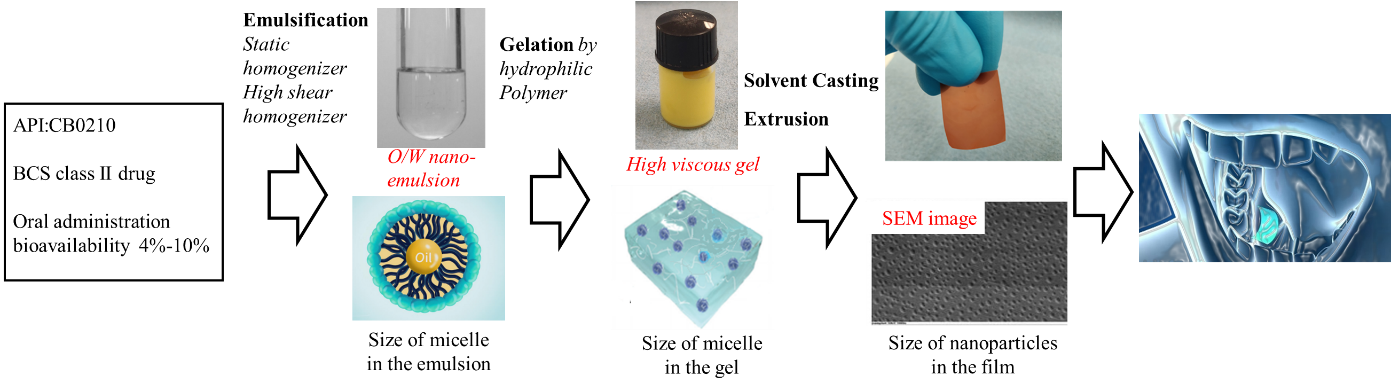

Oral dissolvable films have been considered as a unique alternative approach to conventional oral dosage forms. The films could be administrated via the gastrointestinal tract as conventional dosages or through sublingual/buccal mucosa membranes which could enhance drug bioavailability by avoiding the first-pass effect and improving permeability due to high blood flow and lymphatic circulation. This work has described a state-of-art technic using nano-emulsion/nano-suspension as a precursor for the film to enhance the bioavailability of BCS class II drugs. The drug molecules are consequentially processed through the emulsification, gelation, and film-casting processes. The gelation process is critical to stabilizing the nano-emulsion for the film-casting as well as controlling the drug release process. Furthermore, the size of the nanoparticle on the film has a strong correlation with the size of the micelles in the precursor and the condition of the gelation process. It has been discovered that nanoparticle from 200 nm to 300 nm has shown the highest permeability for sublingual administration. In one example shown in the work, the bioavailability of a low solubilize drug has been increased from 10% to 34% via sublingual administration of the film. The increasing of the bioavailability was thought to be associated with the enhancement of the diffusion process of the drug in the saliva layer above the mucosa membrane and the fact that the presents of the emulsifier help lose the rigid junction of the mucosa cells.

Aqueous Biopolymeric Coatings for Corrosion Protection of Galvanized Steel*

1Hydrometallurgy and Corrosion, Department of Chemical and Metallurgical Engineering (CMET), Aalto University, P.O. Box 16200, Aalto, Espoo FI-00076, Finland.

2Materials Research Centre, College of Engineering, Swansea University, Bay Campus, Crymlyn Burrow, Swansea SA1 8EN, Wales, U.K.

3SPECIFIC, College of Engineering, Swansea University, Bay Campus, Crymlyn Burrow, Swansea SA1 8EN, Wales, U.K.

Email:

* The poster presentation is based on a recently published study, available at https://doi.org/10.1021/acsami.1c08274

This study investigated the utilisation of waste materials from the Biorefining industry for the preparation of colloidal lignin particles (CLPs) through solvent-exchange in water. A solution of kraft lignin in diethylene glycol monobutyl ether (150 g/L) was utilized for the synthesis of CLPs, which demonstrated a coalescing characteristic during drying. The prepared aqueous dispersion of CLPs was combined with a suspension of TEMPO-Oxidized cellulose nanofibrils at different concentrations (1 g/L or 2 g/L), and the aqueous mixture was used for potentiostatic electrophoretic deposition on galvanized steel at different potentials (0.5 V or 3 V). The resultant biopolymeric coatings were dried (21 °C for 12 hours and oven drying at 105 °C for 1 hour) and characterized by electrochemical impedance spectroscopy (EIS) during 15 days immersion in 3.5 wt.% NaCl. It was found that the coatings enhanced the charge transfer resistance of the steel substrate for the whole duration of the test. Such coalescing lignin particles could potentially form the basis for the preparation of sustainable lignin-based aqueous coatings for the corrosion protection of steel surfaces.